DUCTGROVE

LIMITED

Main Menu

Copyright © 2020

DUCTGROVE CONSULTANT ENGINEERS

Last modified: Sept 2020

Consultant Engineers

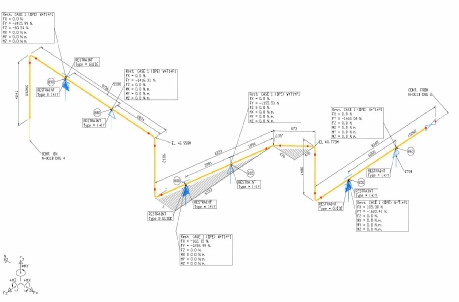

Dynamic Analysis -

THE LAW AND PRESSURE EQUIPMENT

The most important reason stress analysis is carried out is that it is safety and a legal requirement in most countries with legal implications, therefore compliance is normally mandatory, If a design falls within the scope of a design code the design has to be compliant, the operator must always ensure that any calculations are carried out by a Specialist Engineer.

CODE COMPLIANT EQUIPMENT

The Specialist Engineer will in most cases to ensure that the calculated stresses in the plant assessed are within the correct code allowable for all modes of operation.

PIPE STRESS ANALYSIS

WHY SHOULD YOU CARRY

OUT STRESS ANALYSIS